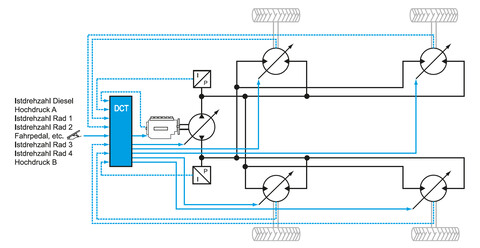

The drive control with traction controller DCT was developed for vehicles that are to be moved with the lowest possible slip with regard to the ground.

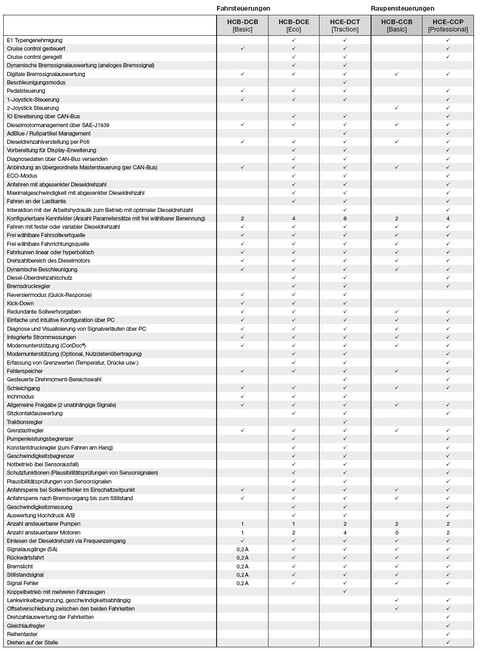

While the DCT enables a ground-friendly driving style in agricultural and forestry machines, it enables a more stable driving style in fast-moving municipal machines. For rail vehicles, driving with slide and skid protection is even required by the German Federal Railway Authority. The DCT drive control was consistently designed to minimise hydraulic components such as flow dividers, pressure controllers, spraying, etc., in order to simplify the design of the machine. The DCT drive control therefore has all the functions of the ECO drive control. All controllers can be activated or deactivated via parameterisation and adapted to the requirements of the current vehicle.

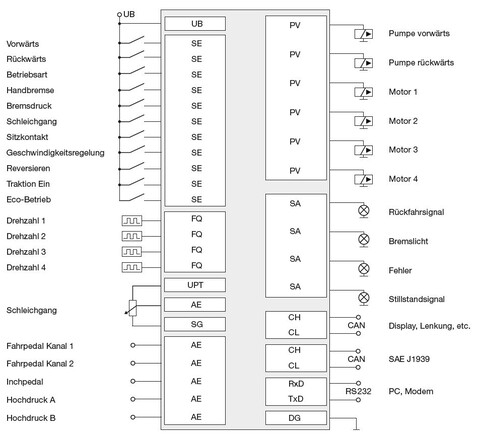

The HCE controller is the standard hardware platform for the DCT. If the DCT is to be integrated into a machine controller, it can easily be ported to another Völkel hardware platform.

The extended functions in detail

Traction control

The traction control reduces the torque at the spinning or locking wheel. This is possible for up to 3 out of 4 wheels. Separate control of axles is also possible if axle motors are used instead of wheel motors. The output torque can be controlled down to zero, taking into account the limit values of the hydraulic motors. Depending on the changed motor displacement, the pump delivery volume is compensated to avoid any unintended change in velocity. The controller has an integrated learning function for simplified adaptation to different vehicles.

Controlled torque range selection

If closed-loop traction control is not desired, DCT supports a controlled variant: The maximum torque available at the hydraulic motor is specified by the driver or by the higher-level control system via an analogue setpoint or via a digitally selected fixed value. The drive control then acts as a torque limiter, so that soil-friendly driving is possible. Unlike the closed-loop traction control, this operating mode does not continuously drive with the maximum possible torque.

Acceleration mode

The acceleration mode is a special function for railway vehicles. If activated, the setpoint of the driving lever is not a measure for the target velocity, but for the acceleration of the vehicle. If the driving lever remains in the centre position, the vehicle maintains the current speed. A driver safety switch (SIFA, dead man’s switch) must always be activated when operating in the acceleration mode.

Coupling operation of several vehicles

If several vehicles with hydrostatic drives are coupled, hydraulic tensions must be avoided so that no vehicles in the combination are towed or pushed by the others. Travel pressure control allows each hydraulic circuit to make a positive contribution to propulsion. The same applies to rail vehicles that have one hydraulic circuit per bogie.

Extended ECO operation

The DCT drive control offers an option to interact with the control of the work hydraulics. In this way, the diesel engine can be controlled according to demand and can also be operated at the load edge to power the work hydraulics. The prioritisation of the components in the different operating modes is controlled by the DCT.

AdBlue and soot particle management

If the diesel engine is operated at the optimum operating point, AdBlue consumption is lower and soot particle filter contamination will be slower. If it is not possible to operate the machine in this way due to external circumstances, measures are required on the part of the machine controller. The advanced diesel management of modern engines is supported by a Völkel display. Depending on the AdBlue tank level and the condition of the soot particle filter, for example, the engine power is limited or regeneration is carried out.

E1 type approval

In order to enable registration of the machine for European road traffic, the hardware platform of the DCT controller has an E1 type approval.