cylinder-synchronization control

HCB-CSC

2 axles with 2 solenoids per controller.

Synchronization of up to 20 cylinders

The application controls up to 20 cylinders in position and speed synchronism to reach a target position. Due to a braking curve the speed is reduced dependent on the distance to the target position. That enables a smooth braking behaviour.

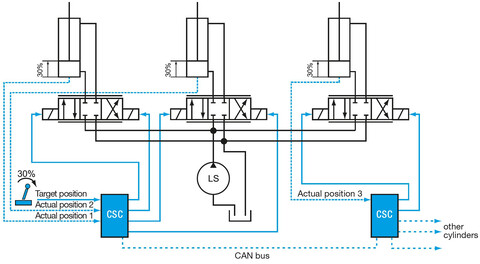

The standard ECU for this controller is the HCB controller, which can be used to control 4 solenoids (two 4/3-way valves). If the CSC controller is used to synchronize more than 2 cylinders several controllers are networked via CAN bus. The operating modes “Analog” and “Digital” are available, through which an analog setpoints and selectable digital fixed values can be controlled. The positions are approached via adjustable ramps. The maximum speed at which the machine moves into position can be set using an additional analog value.

Another method to synchronize the position of more than 2 cylinders per controller is to port the function to another hardware platform. The same applies to the interaction of the CSC software with other Völkel standard controllers or the integration of the functionality into a Völkel machine controller.

The cylinder synchronism control replaces a hydraulic flow divider. It is easily possible synchronize cylinders, which have a large spatial distance to each other. In contrast to a fixed hydraulic installation, it is possible to move cylinders with different offsets towards each other. The advantage over purely hydraulic control is the variability of the control.

The synchronization controller can be used as part of an electronic track rod (special control with steering angledependent offset), for lifting platforms, in material feeds with cascaded sliders, etc.

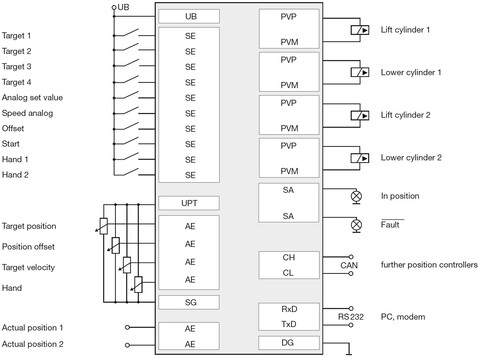

Inputs and outputs

- Digital inputs for mode changeover, for fixed values, manual operation. Can be parameterized as enabled for position control with fixed position difference between cylinder 1 and 2, allowing fine adjustment of the target position, etc.

- Analog inputs for the set values for position and velocity in manual operation, fine adjustment of the target position, actual position of cylinders 1 and 2

- Proportional outputs with current feedback measurement for 2 cylinders

- Status outputs, for the status of input/output faults, position errors, in position, limitation On/Off active

- CAN interface for communication between the axles